Industrial environments demand interfaces that perform under pressure. LED-backlit keypads increase operational efficiency by delivering clear visibility and precise control. Operators rely on these devices for tasks that require accuracy. An industrial metal keypad withstands harsh conditions and maintains functionality, making it a dependable choice for critical applications.

Key Takeaways

- LED-backlit keypads improve visibility and reduce errors by providing bright, adjustable lighting that helps operators work accurately even in low-light conditions.

- These keypads are built with durable materials and sealed designs that protect against dust, moisture, chemicals, and extreme temperatures, ensuring reliable performance in harsh industrial environments.

- Customizable lighting and keypad features allow operators to tailor controls for comfort and efficiency, boosting safety and speeding up workflows in various industries.

Enhancing Visibility and Usability with LED-Backlit Keypads

Solving Low-Light and Poor Visibility Issues

Industrial environments often present lighting challenges. Operators may work in dimly lit factories, outdoor sites at night, or inside control rooms with minimal illumination. LED-backlit keypads address these issues by delivering high-brightness illumination directly to each key. This targeted lighting ensures that operators can clearly see and identify controls, even in complete darkness.

LED technology stands out for its adjustable brightness. Users can tailor the intensity to match ambient conditions, which supports both comfort and accuracy. LEDs also offer a long operational lifespan and consume minimal energy, making them ideal for continuous use in demanding settings such as manufacturing floors and medical equipment. Compared to older backlighting methods like electroluminescent panels or fiber optics, LEDs provide superior brightness and durability.

Operators benefit from fast key positioning and reduced risk of input errors, especially during critical or emergency situations. Illuminated keys act as visual prompts, guiding users to the correct controls and improving both safety and productivity.

Key features that enhance visibility in low-light environments include:

- High luminous intensity LEDs for strong, even illumination.

- Use of high-transparency inks and diffuser films to distribute light uniformly and eliminate bright spots.

- Backlit membrane switches that enable rapid, accurate key identification.

Improving User Interface Clarity

Clarity in user interfaces is essential for efficient operation. LED-backlit keypads improve clarity by providing consistent, uniform lighting across all keys. This eliminates shadows and dark areas, which can cause confusion or slow down response times. Adjustable brightness and color options further enhance usability, allowing operators to customize the interface for optimal comfort and performance.

Backlit keypads also reduce eye strain. Operators can adjust the lighting to suit their preferences, which helps maintain focus during long shifts. The sealed design of many backlit membrane switches protects against dust and moisture, ensuring reliable operation and clear visibility over time.

- Sealed construction increases reliability and longevity, even in harsh industrial settings.

- Energy-efficient LEDs reduce power consumption and operating costs.

- Durable materials and backlighting technology maintain functionality despite heavy usage.

The combination of tactile feedback and illuminated keys supports accurate, confident operation. Users can quickly locate and activate the correct controls, minimizing mistakes and improving workflow efficiency.

Customizable Lighting for Industrial Applications

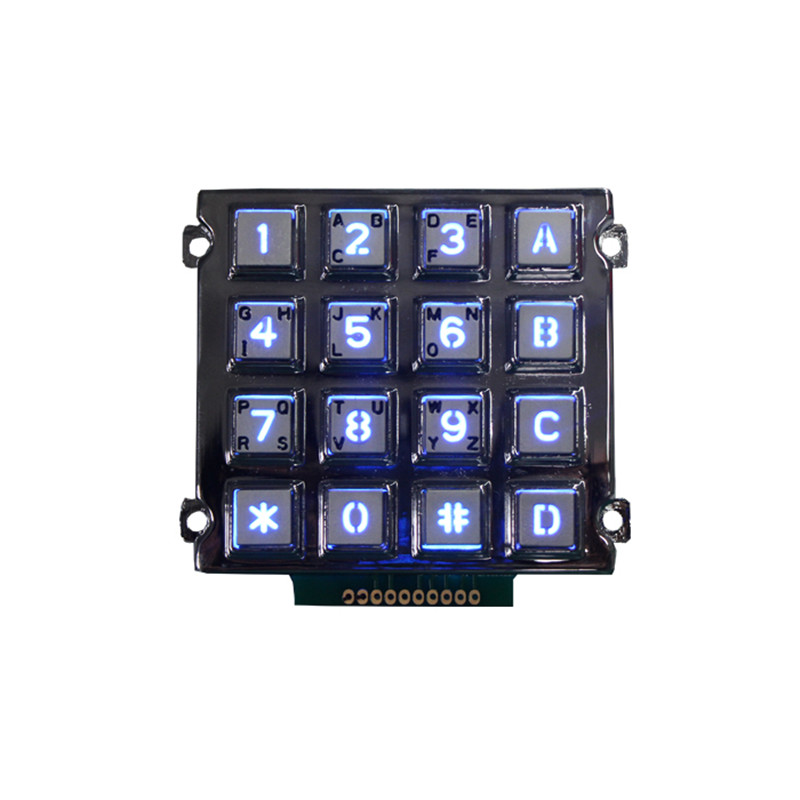

Customization plays a vital role in industrial keypad design. LED-backlit keypads offer a wide range of options to meet specific application requirements. Manufacturers can select from materials such as stainless steel, silicone rubber, or zinc alloy to ensure durability and resistance to environmental hazards. Painting techniques, including dual or tri-layer coatings with laser etching, create illuminated icons that remain visible under all conditions.

Keypads can be designed with waterproof and vandal-resistant features, making them suitable for outdoor or high-risk environments. LED colors are customizable to match branding or enhance visibility for particular functions. Custom legends and key labeling, achieved through laser etching, allow operators to prioritize frequently used controls and simplify complex workflows.

| Feature | Description | Impact on Workflow Efficiency |

|---|---|---|

| Adjustable LED Illumination | Brightness can be fine-tuned, with advanced dimmable LEDs | Enhances visibility, reduces errors, and speeds up operation |

| Modular Design with Custom Cut-outs | Rapid prototyping and adaptation to specific input needs | Reduces confusion, enables quick adaptation to workflows |

| High Brightness Backlight (260-nit) | Exceeds industry standards for visibility, even in direct sunlight | Maintains readability, prevents workflow delays |

| Durable Industrial-grade PCB & LEDs | Reliable operation in harsh environments | Reduces downtime, ensures consistent performance |

Additional features such as auto-dimming backlights, ambient light sensors, and programmable LED feedback patterns further enhance usability. These options allow the keypad to adapt to changing lighting conditions and provide clear status indications for each button. Customizable button text and layouts enable operators to tailor the interface to their specific tasks, increasing speed and reducing the likelihood of errors.

Customizable lighting not only improves visibility but also supports compliance with safety regulations by reducing operator errors and enhancing overall process efficiency.

LED-backlit keypads have become essential in industries such as manufacturing, healthcare, transportation, and automation. Their ability to provide clear, reliable, and customizable interfaces ensures that operators can perform their tasks efficiently, regardless of environmental challenges.

Durability and Reliability of Industrial Metal Keypad Solutions

Robust Construction and Material Selection

Industrial metal keypad solutions rely on robust construction to withstand the demands of harsh environments. Manufacturers select materials such as stainless steel, coated metals, and aluminum for their high strength and corrosion resistance. These materials ensure the keypad remains functional in marine, industrial, and outdoor settings, where exposure to saltwater, humidity, and physical impact is common.

| Aspect | Details |

|---|---|

| Common Materials | Stainless steel (primary), coated metals, aluminum |

| Durability Features | High strength, corrosion resistance, suitable for harsh environments |

| Durability Ratings | IP65 or higher (including IP67, IP66, IP68) indicating strong water and dust resistance |

| Environmental Suitability | Resistant to saltwater, humidity, physical impact, temperature fluctuations |

| Typical Applications | Marine (ships, oil rigs), factories, outdoor kiosks, military, aerospace |

Stainless steel and aluminum provide long-lasting performance and reduce maintenance costs. High IP ratings, such as IP65, IP66, and IP68, confirm the keypad’s ability to resist water, dust, and temperature extremes. These features make the industrial metal keypad a preferred choice for outdoor security systems and heavy machinery.

Metal domes inside these keypads can endure over 1,000,000 presses, demonstrating exceptional durability. Rubber keypads, often used in safety and construction, also offer resistance to moisture and extreme weather. LED-backlit designs use silicone materials to diffuse light, ensuring both durability and user comfort.

Industry standards further validate the robustness of these keypads:

| Standard/Rating | Description |

|---|---|

| IP Ratings | Protection against solids and liquids; IP65–IP68 ensure waterproof and dustproof capabilities |

| IK Ratings | Mechanical impact resistance, measured in joules |

| ATEX Standards | Safety certification for explosive environments |

| MIL-STD-810G/F | Military standard for environmental stress resistance |

| MIL-STD-461 | Electromagnetic compatibility requirements |

Protection Against Dust, Moisture, and Chemicals

Industrial environments expose keypads to dust, moisture, and aggressive chemicals. The industrial metal keypad addresses these challenges with seamless silicone construction and full sealing. Many models achieve IP68 certification, which guarantees complete protection against dust ingress and prolonged water immersion. This level of protection is essential for food processing, manufacturing, marine, and medical applications.

- Seamless silicone prevents liquid and particle infiltration.

- IP68 certification ensures the keypad remains operational after exposure to water and dust.

- Washable and disinfectable surfaces support hygienic environments.

Silicone rubber keypads resist chemical exposure due to their chemical stability and abrasion resistance. They withstand oils, greases, solvents, and disinfectants without degrading. Sealing features act as gaskets, enhancing protection against environmental hazards. Translucent silicone rubber allows uniform LED backlighting, while laser etching creates precise illuminated legends that maintain protective qualities.

Design strategies for membrane switches, including LED-backlit keypads, focus on encapsulation and protective coatings. These features shield sensitive components from moisture, debris, UV light, and corrosive substances. Accelerated lifecycle tests simulate temperature extremes, moisture, and chemical exposure to validate reliability before production.

The combination of robust materials, advanced sealing, and chemical resistance ensures that the industrial metal keypad delivers reliable performance in the most demanding environments.

Consistent Performance in Extreme Conditions

Industrial metal keypad solutions must operate reliably in extreme temperatures, high humidity, and under mechanical stress. Keypads with LED-backlighting maintain consistent performance across a wide temperature range. For example, the Maple Systems Alphanumeric OIT Series operates from -10°C to 65°C, while some standard keypads function from -40°C to +70°C. This capability supports use in both refrigerated facilities and hot outdoor locations.

| Keypad Model | Operational Temperature Range |

|---|---|

| Maple Systems Alphanumeric OIT Series (LED-backlit) | -10°C to 65°C |

| PowerKey 1400 CAN (Standard Keypad) | -40°C to +70°C |

Membrane key switches, including LED-backlit models, typically last 5 to 10 million keystrokes. Metal domes and copper flex circuitry further enhance durability by resisting thermal shock and reducing switch bounce. Light Guide Film (LGF) technology distributes LED light evenly, preventing hot spots and light leakage. This design not only improves visual quality but also reduces power consumption.

- LED-backlit keypads may require slightly higher maintenance due to additional components, but protective features minimize wear.

- Non-backlit keypads have fewer failure points but lack the visibility and user interface benefits of LED-backlit designs.

- Common failure modes, such as uneven lighting and light leakage, are mitigated by LGF and robust construction.

Industrial metal keypad solutions deliver reliable operation, even when exposed to temperature fluctuations, moisture, dust, and chemicals. Their advanced engineering ensures consistent performance, making them indispensable in critical industrial applications.

LED-backlit keypads, including the industrial metal keypad, deliver superior visibility and reliability. Companies report fewer errors, faster workflows, and lower maintenance costs. Enhanced safety features, such as status indicators and rugged construction, support consistent performance. These keypads address critical industrial challenges and provide a strong return on investment.

FAQ

What industries benefit most from LED-backlit keypads?

Manufacturing, healthcare, transportation, and automation industries use LED-backlit keypads. These sectors require reliable, visible, and durable interfaces for daily operations.

How do LED-backlit keypads improve safety?

LED-backlit keypads reduce input errors and help operators identify controls quickly. Enhanced visibility supports safer workflows, especially in emergency or low-light conditions.

Can operators customize the lighting on these keypads?

Operators can adjust brightness, select colors, and program feedback patterns. Customization improves comfort, workflow efficiency, and compliance with specific application requirements.