Harsh industrial environments quickly destroy standard phones. Dust, water, and extreme temperatures demand tough communication tools. A rugged industrial telephone handset offers essential, uninterrupted connectivity. This is vital for safety, efficiency, and continuous operations. Communication downtime costs organizations in the Communications and Media sector an estimated $143 million annually, showing how crucial robust solutions are.

Key Takeaways

- Rugged telephone handsets are built tough. They resist dust, water, and extreme temperatures. This makes them perfect for harsh industrial places.

- These durable phones improve safety and work efficiency. They also save money. They break less often than regular phones.

- Many industries use rugged handsets. These include factories, construction sites, and mines. They ensure clear communication in tough conditions.

Defining a Rugged Industrial Telephone Handset

When you hear “rugged,” what comes to mind? For an industrial telephone handset, it means a device built to laugh in the face of conditions that would destroy a regular phone. These aren’t your everyday smartphones; they are specialized tools designed for extreme resilience and unwavering performance.

Key Durability Features and Standards

A truly rugged industrial telephone handset boasts specific features that set it apart. First, it must have strong Ingress Protection (IP) ratings, often IP66, which means it is dust-tight and can withstand powerful water jets. Manufacturers build these handsets from light alloys, and they often draw power directly from the telephone network. The cord itself is usually a screened cable, protected by a stainless steel spiral.

You will also find a built-in ringer that blasts sound over 90 decibels, plus an LED for clear visual alerts. These phones are robust and sturdy, made from materials that resist damage and perform well in harsh environments, even in public places where vandalism might be a concern. Vandal-resistant models take it a step further, featuring armored cables, heavy-duty amplified handsets, and thick stainless steel panels.

These devices are ready for both indoor and outdoor use, offering reliable operation. They come with various connectivity options like Analog, SMART Analog, or VoIP. Their weatherproof ratings range from NEMA 3R/IP65 to NEMA 4X/IP66, and they often have conformally coated circuit boards to stop corrosion. To ensure clear conversations in noisy areas, they include noise-cancelling microphones. Essentially, these handsets are designed to endure almost anything and stay fully functional, even in hazardous zones.

To prove their toughness, many rugged devices meet military standards. The U.S. Department of Defense created MIL-STD-810G and MIL-STD-810H to test military equipment in harsh environments. These standards cover a wide array of conditions, including extreme temperatures, humidity, vibration, and shock. Passing these rigorous tests ensures a device works in the most challenging situations. Industries like construction and manufacturing use these standards as a benchmark for durability and reliability. For example, MIL-STD-810G includes tests for low pressure, high and low temperatures, temperature shock, rain, humidity, sand and dust, immersion, vibration, and shock, among many others.

Robust Materials and Construction for Longevity

How do these tough phones differ from the sleek device in your pocket? Let’s look at the core differences:

| Feature | Rugged Telephones | Consumer-Grade Telephones |

|---|---|---|

| Design & Weight | Bulkier, heavier, built for tough environments | Slim, lightweight, stylish, less resistant to damage |

| Durability | Purpose-built for demanding conditions (drops, dust, water, extreme temperatures) | Sleek, affordable, designed for everyday use, fragile in harsh environments |

| Customization | Highly customizable with add-ons (barcode scanners, specialized ports, RFID readers) | Standardized hardware and design, limited flexibility, rarely customizable with job tools |

| Display | Optimized for outdoor readability, glove use, sunlight visibility | Endless screen options, but often lack outdoor optimization |

Rugged telephone handsets feature reinforced casings, shock resistance, and special seals to keep out dust, water, and extreme temperatures. They are specifically engineered to work in fast-paced, demanding environments. These devices offer proven protection against fluctuating temperatures, vibrations, pressure, and exposure to water and dust. Unlike consumer-grade devices, which would likely fail, rugged phones often have high IP-ratings to withstand harsh conditions. Their construction includes features like excellent screen resilience to light and moisture, superior drop-resistance, and advanced screen technologies such as Gorilla Glass, all built for challenging work environments.

Manufacturers use specific materials for these casings to ensure maximum impact resistance. Common choices include aluminum alloy enclosures, GRP (fiberglass reinforced polymer), 304 stainless steel shells, and SMC (sheet molding compound) housings. A solid stainless steel body is also a popular option for its sheer strength.

Internal component sealing plays a huge role in how long a rugged telephone handset lasts. This sealing stops particles and water from getting inside, which are common causes of device failure. Seals around ports, speakers, and internal components protect against dust and water. Dust resistance is vital because particle infiltration can damage internal parts, leading to problems like charging issues, distorted speakers, or button malfunctions within a few years of heavy use. Water-resistant sealing is another key protective feature, greatly reducing the chance of water damage. The quality of these sealing materials directly affects how well a phone maintains its integrity over time. However, seals can degrade from drops, temperature changes, or exposure to corrosive liquids, meaning water resistance is not always permanent.

Critical Benefits of Rugged Handsets in Industrial Settings

Rugged telephone handsets offer significant advantages in tough industrial environments. They do more than just connect people; they actively enhance safety, boost productivity, and save money over time.

Enhancing Safety and Emergency Response Capabilities

Safety is paramount in industrial settings. Rugged handsets play a crucial role in protecting workers. They ensure clear, reliable communication during daily tasks and critical emergencies. These devices are waterproof and dustproof, often rated IP66–IP67, protecting against dust and powerful water jets. They also operate reliably in extreme temperatures, from -40°C to +65°C. Their heavy-duty housing resists impacts, vibrations, chemicals, and salt mist. Workers can instantly connect to control centers or emergency services using an emergency hotline function. Noise-cancelling audio ensures clear conversations even in very loud areas. Features like panic buttons, fall detection sensors, and SOS calls allow responders to quickly call for help. Built-in radios or push-to-talk capabilities further enhance team coordination.

Improving Operational Efficiency and Productivity

Rugged handsets significantly improve how efficiently teams work. They offer long battery life, ensuring continuous operation through long shifts and reducing downtime. These devices also come with customization options. For example, they can have push-to-talk (PTT) buttons, barcode scanners, or specialized sensors. These tailored functionalities meet unique industrial needs, making tasks faster and more accurate. An industrial telephone handset built for these conditions minimizes interruptions, keeping operations smooth and productive.

Achieving Cost Savings Through Durability

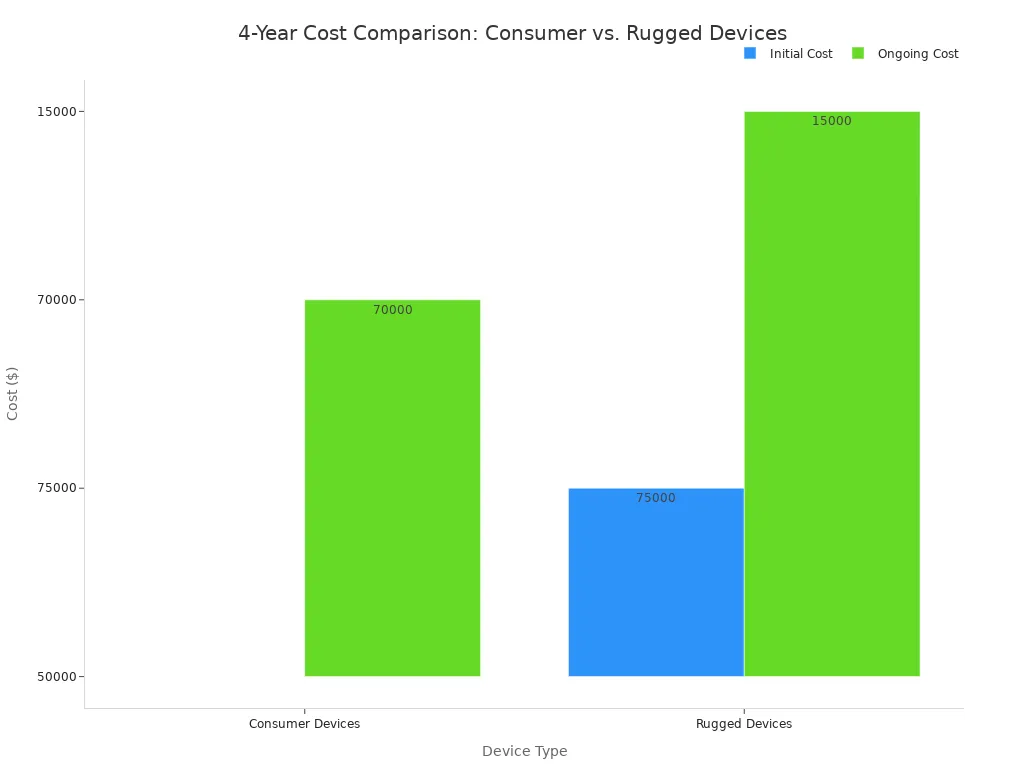

Investing in rugged handsets leads to substantial long-term cost savings. These devices have a much lower failure rate, as low as 5%, compared to consumer devices, which can fail up to 30% of the time. This means fewer breakages and replacements. Rugged devices also last longer, typically 3-5 years or more, while consumer phones last only 1.5-2 years. When a device does fail, rugged handsets cause only about 1 hour of downtime, compared to over 4 hours for consumer devices. This reduced downtime keeps productivity high. Over four years, a company with 100 devices could save up to $30,000 by choosing rugged options.

Applications of Rugged Industrial Telephone Handsets

Rugged telephone handsets find their home in many tough places. They provide reliable communication where standard phones simply cannot survive. Let’s explore some key industries that depend on these durable devices.

Manufacturing Plants and Factories

Manufacturing facilities demand crystal clear communication. This ensures safety, boosts productivity, and keeps operations running smoothly. These plants often have loud environments and cover large areas. Miscommunication can lead to big safety hazards or production delays. Rugged handsets offer noise-cancelling technology and long battery life. They also come with safety features like Lone Worker and Man Down alerts. These tools help teams coordinate tasks and respond quickly to emergencies.

Construction Sites and Outdoor Operations

Construction sites are notoriously harsh. Workers face drops, dirt, shock, dust, and extreme temperatures. They also deal with heavy salt, fog, and even the risk of submersion in water. Rugged handsets are built to withstand these conditions. They ensure workers always have access to critical information. This reduces the need for constant replacements and repairs. You often see these devices on highways, in tunnels, or on cranes.

Mining, Oil & Gas, and Hazardous Zones

In places like oil rigs, power plants, and mining sites, safety is paramount. These environments often contain explosive atmospheres. Here, rugged handsets need special certifications like ATEX. This certification ensures the devices are intrinsically safe. They limit electrical and thermal energy, preventing ignition. These phones offer reliable network access, even in remote areas. They also include advanced communication features like Push-to-Talk and safety alarms.

Warehousing and Logistics Hubs

Warehouses and logistics hubs are busy places. They often experience dust, wind, and heavy vibrations. Rugged devices withstand these extreme conditions. They can even survive drops and temporary submersion. Many of these handsets feature Push-to-Talk (PTT) capabilities. This allows instant communication across teams, replacing traditional two-way radios. Systems like DuraFon offer unmatched range and durability, ensuring clear communication over large areas.

Choosing the Right Rugged Industrial Telephone Handset

Selecting the right rugged telephone handset for your industrial environment is a big decision. It is not just about picking the toughest phone; it is about finding the perfect match for your specific needs. A careful choice ensures reliable communication, worker safety, and long-term cost savings.

Assessing Environmental Conditions and Specifications

Before you even look at a phone, you must understand where people will use it. What kind of environment will the handset face? Is it extremely hot or cold? Will it get wet or dusty? Answering these questions helps you choose the right level of ruggedness.

First, conduct an in-depth analysis of your operational environment. Think about the specific tasks workers perform and what they need from a device. What works for a field sales team might not suit a manufacturing plant.

Next, evaluate the technical specifications. Consider processor speed, memory, storage, and connectivity options. These factors are crucial for the device’s performance. You also need to assess the device’s durability. Look for resistance to dust, moisture, shock, and extreme temperatures. Different levels of ruggedness exist, from “ruggedized” to “ultra-rugged,” each suited for varying challenges.

Manufacturers test rugged devices against strict standards to prove their toughness. For example, MIL-STD-810G is a U.S. Department of Defense standard that tests equipment in harsh conditions. This includes methods for:

- High Temperature (Method 501.4): Devices perform in heat up to +71°C, like in deserts or engine rooms.

- Low Temperature (Method 502.4): They work in extreme cold, down to -57°C, for arctic regions.

- Humidity (Method 507.4): Tests check for moisture absorption and corrosion over 10–15 days at high humidity.

- Salt Fog (Method 509.4): This simulates marine conditions, exposing equipment to salt spray for days to check corrosion.

- Sand and Dust (Method 510.4): Devices face fine or coarse particles blasted at high speeds to test against ingress and abrasion.

- Vibration (Method 514.5): Tests ensure durability against vibrations from transportation like ships or vehicles.

- Shock (Method 516.5): This measures survival during impacts, including drops and crash loads.

Another key specification is the Ingress Protection (IP) rating. This rating tells you how well a device resists dust and water. For instance, an IP68-rated device is dust-tight and can handle submersion in water beyond one meter. A higher number means better protection. Manufacturers also test drop resistance, checking how high a device can fall onto concrete without damage.

Understanding Connectivity Options for Industrial Use

Reliable connectivity is the backbone of any communication system. Rugged industrial telephone handsets offer various options to keep your team connected, whether they are on the move or at a fixed station.

Many modern rugged cordless IP phones use Wi-Fi or DECT (Digital Enhanced Cordless Telecommunications) for mobility. For example, models like the Grandstream WP825 only need a Wi-Fi AC connection, eliminating the need for a central base. Other devices, such as the Snom M70, M80, and M90, are industrial cordless IP DECT handsets. They often meet MIL-STD-810G standards for durability. You can connect multiple cordless handsets to a DECT base station, like the SNOM M900, which uses professional multi-cell DECT technology for wider coverage.

These phones provide enterprise-grade calling over WLAN, connecting to Unified Communication Managers. They offer seamless compatibility with Wi-Fi networks or full-range DECT endpoints. Newer models feature Dual-Band Wi-Fi 6, which provides faster speeds and greater capacity, reducing network congestion. Wi-Fi 6 also supports seamless 802.11k/v/r roaming, meaning calls stay connected as workers move between access points. For high security, these devices often support the WPA3 Enterprise protocol.

Ergonomics and User Experience in Demanding Environments

Even the toughest phone is useless if workers cannot use it effectively. Ergonomics and user experience are vital, especially in demanding industrial settings.

Consider how workers will interact with the device. Will they wear thick gloves? Many rugged handsets feature enhanced touch capabilities, allowing workers to use the phone with gloves on, even in challenging conditions like rain. This “glove-ready” feature is crucial for productivity.

The user interface should be intuitive, and controls should be easy to operate. A user-friendly design helps workers perform tasks efficiently. Screen visibility is another important factor. Look for features like anti-glare coatings and high-brightness settings. These ensure the screen remains visible and readable, even in intense sunlight or other bright outdoor conditions. The device’s form factor also matters; some tasks might benefit from a larger screen for digital instructions, while others need a pocket-sized device.

Specialized Features for Specific Industrial Needs

Rugged handsets come packed with specialized features designed to meet the unique demands of industrial environments. These features go beyond basic calling, enhancing safety, efficiency, and communication.

One of the most critical features is Push-to-Talk (PTT). PTT handsets offer smooth, real-time communication with a single button press, much like a two-way radio. This improves coordination and operational efficiency in emergency response, security, or manufacturing facilities. Many devices integrate with PTT solutions like Microsoft Teams.

Enhanced audio is also essential. Loud industrial environments require noise-canceling microphones and powerful loudspeakers to ensure clear communication. Some handsets even offer “Push-to-Mute” (PTM) for specific situations.

Battery life is another critical factor. Look for long-lasting batteries, often providing 14 hours of continuous use or more. Features like fast-charging capabilities, swappable batteries, and heavy-duty pogo pin connectors for charging ensure uninterrupted operation during long shifts.

For safety, many rugged phones include dedicated emergency buttons and man-down alarms. Man-down systems detect if a worker falls or becomes incapacitated by monitoring the device’s angle and motion. If triggered, these systems send immediate alerts to designated responders, often including the worker’s name and real-time GPS location. This allows for quick response and can prevent serious injuries. Some devices, like the Atlas S10 or PNC460, feature a physical SOS button and true man-down detection.

Other specialized features include:

- Reinforced ports and connectors: These prevent internal damage from repeated plugging/unplugging or moisture exposure.

- Security features: Hardware-based security platforms (like Samsung Knox), remote device management, and user authentication (e.g., fingerprint) protect sensitive data.

- Powerful capabilities: Front and rear cameras, Near-Field Communication (NFC) for wireless data transfer, and Internet of Things (IoT) integrations can add significant value.

- Certifications: For hazardous zones like oil and gas or mining, ATEX certification ensures the device is intrinsically safe and will not cause ignition. For aerospace and defense, MIL-STD-810G/H standards guarantee reliability in high-risk operations.

Choosing the right rugged industrial telephone handset means carefully matching these features to your specific operational needs.

Rugged telephone handsets are essential tools. They ensure safety, efficiency, and continuous operations in tough industrial places. Choosing the right rugged solution is a smart investment. It protects both personnel and daily work. Ultimately, these durable communication solutions are vital for modern industrial success.

💡 Remember, reliable communication keeps your team safe and productive.

FAQ

### What makes a telephone handset “rugged”?

A rugged handset meets tough standards like IP66 for dust and water resistance. It also passes military-grade tests (MIL-STD-810G) for drops, extreme temperatures, and vibrations. 🛡️

### Why should industries choose rugged handsets over standard phones?

Rugged handsets last much longer and break less often. They save companies money on replacements and repairs. They also ensure reliable communication in harsh conditions, boosting safety and efficiency.

### Where do rugged industrial telephone handsets get used?

You find rugged handsets in places like manufacturing plants, construction sites, mines, and oil rigs. They are essential for communication in any tough or hazardous environment.