Industrial telephone handsets made from ABS plastic shine in industrial settings. Their strength and durability make them perfect for tough environments. Many industries rely on these industrial telephone handsets because they are lightweight and easy to handle. Plus, the cost-effectiveness of ABS allows for high-quality production without breaking the bank.

Key Takeaways

- ABS plastic telephone handsets are highly durable, making them perfect for tough industrial environments. They can withstand impacts and harsh conditions, ensuring reliable communication.

- These handsets resist moisture and corrosion, which helps them maintain functionality even in wet or chemically exposed settings. This feature extends their lifespan and reduces replacement costs.

- Safety and ergonomics are prioritized in the design of ABS handsets. They are non-toxic, lightweight, and user-friendly, making them ideal for workers in demanding industrial jobs.

Exceptional Durability of Industrial Telephone Handsets

When it comes to durability, industrial telephone handsets made from ABS plastic truly stand out. Their ability to withstand tough conditions makes them a favorite in various industries.

Impact Resistance

One of the key features of ABS plastic is its impressive impact resistance. This material can absorb shocks without cracking, which is crucial for telephone handsets used in bustling industrial environments. In fact, ABS scores about 200 J/m in impact tests, indicating its capability to handle hard bumps effectively.

- Impact resistance tests like the Notched IZOD Impact and Gardner Impact tests show that ABS plastic performs well, even though it may not be as tough as polycarbonate.

- Despite this, ABS remains a cost-effective choice for general use. It excels in heat resistance and dimensional stability, making it suitable for high-temperature applications.

This combination of properties ensures that industrial telephone handsets can endure the rigors of daily use without compromising performance.

Long Lifespan

Another advantage of ABS plastic telephone handsets is their long lifespan. These handsets are designed to last, reducing the need for frequent replacements.

- Durability/Vandal Resistance: ABS handsets can withstand high impact forces, with ratings around 200 N for base models and even higher for advanced versions.

- Maintenance: Many models come with replaceable components, simplifying upkeep in busy environments.

A table below summarizes the durability features of different ABS plastic telephone handset models:

| Feature | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Durability | Standard ABS coating | +15% reinforced coating | +30% ultra-durable coating |

| Audio Clarity | Basic transmission | Enhanced noise reduction | Premium crystal-clear audio |

| Vandal Resistance | Meets basic standards | Exceeds by 15% | Exceeds industry benchmarks by 30% |

With such robust features, it’s clear that ABS plastic telephone handsets are built to last, making them an ideal choice for industrial settings.

Environmental Resistance of ABS Plastic

ABS plastic offers remarkable environmental resistance, making it a top choice for industrial telephone handsets. Two critical aspects of this resistance are moisture and corrosion, both of which can significantly impact the performance and longevity of communication devices in demanding environments.

Moisture Resistance

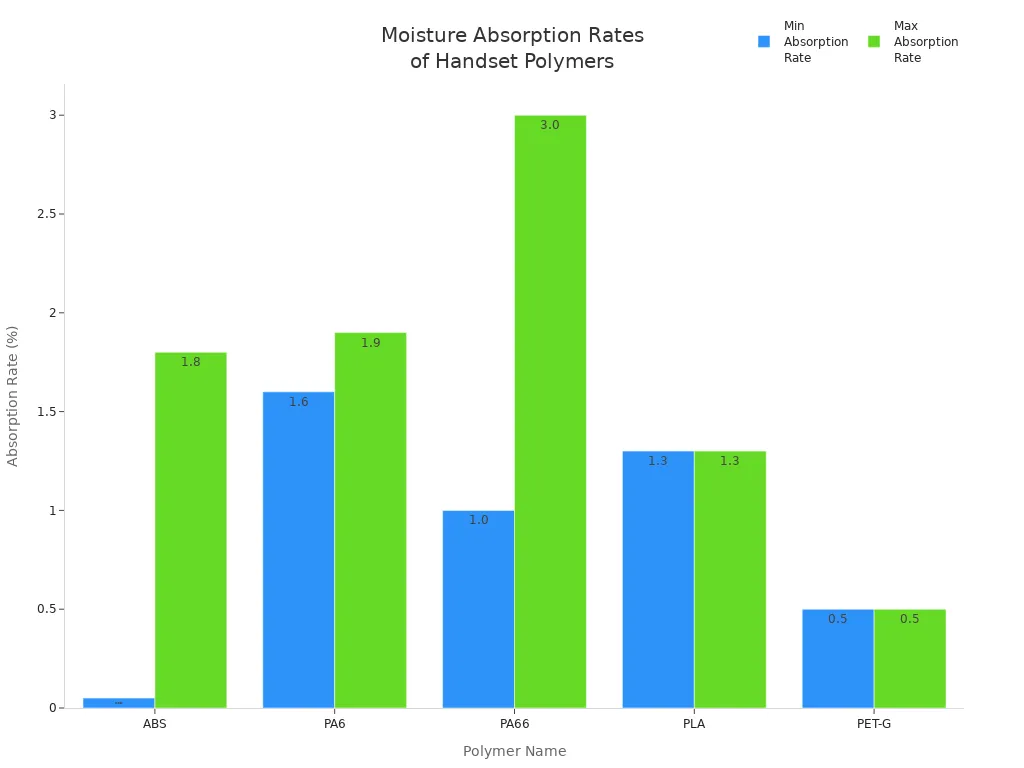

Moisture can wreak havoc on electronic devices, but ABS plastic stands strong against it. Research shows that ABS can absorb moisture up to a maximum of 1.1% after prolonged exposure to humid conditions. This absorption rate is lower than that of other materials like PLA, which can reach 1.3%, and PA6, which can absorb between 1.6% and 1.9%.

- Key Findings:

- Halidi and his team discovered that ABS filament moisture absorption stabilizes at a certain point, affecting its stickiness and flow.

- Wichniarek’s research indicated that moisture content in ABS can vary from 0.1% to 0.6%, which can impact manufacturing processes and mechanical properties.

This moisture resistance ensures that industrial telephone handsets maintain their functionality even in wet environments. The table below summarizes the moisture absorption rates of various polymers:

| Polymer Name | Min Value(%) | Max Value(%) |

|---|---|---|

| ABS | 0.05 | 1.80 |

| PA6 | 1.6 | 1.9 |

| PA66 | 1.0 | 3.0 |

| PLA | 1.3 | 1.3 |

| PET-G | 0.5 | 0.5 |

Corrosion Resistance

In addition to moisture, industrial environments often expose devices to corrosive substances. ABS plastic is engineered to resist these challenges effectively. Its chemical resistance allows it to withstand exposure to various industrial chemicals without degrading. This feature is crucial for maintaining the integrity of industrial telephone handsets, especially in settings where spills or chemical exposure is common.

- Durability Against Elements: ABS plastic telephone handsets are designed to endure extreme temperatures, water, dust ingress, and physical impacts. This durability ensures reliable performance in demanding conditions.

- Vandal Resistance: Many ABS handsets are also vandal-resistant, making them suitable for emergency communication in industrial settings.

With these properties, ABS plastic telephone handsets not only survive but thrive in harsh environments, ensuring that communication remains uninterrupted.

Safety and Ergonomics in Industrial Settings

When it comes to industrial settings, safety and ergonomics play a crucial role. ABS plastic telephone handsets are designed with these factors in mind, ensuring that users can communicate effectively without compromising their safety.

Non-Toxic Materials

One of the standout features of ABS plastic is that it is non-toxic. This means that workers can use these handsets without worrying about harmful chemicals. In fact, many ABS plastic telephone handsets meet strict safety certifications. For example, they often hold certifications like UL94 V-0, which indicates resistance to ignition and fire. This is essential in environments where flammable materials are present.

Safety Certifications:

Certification Description IECEx Certification for equipment used in explosive atmospheres, ensuring safety in hazardous environments like oil refineries. ATEX European certification for equipment intended for use in explosive atmospheres, similar to IECEx. UL94 V-0 Flame rating indicating the material’s resistance to ignition and fire, essential for safety in industrial settings.

User-Friendly Design

The design of ABS plastic telephone handsets also prioritizes user comfort. They feature ergonomic shapes that fit comfortably in the hand, reducing strain during long conversations. The buttons are easy to press, even with gloves on, making them ideal for industrial workers who often wear protective gear.

Moreover, these handsets are lightweight, which adds to their usability. Workers can easily carry them around without feeling weighed down. This thoughtful design ensures that communication remains seamless, even in the busiest environments.

Regulatory Requirements:

Certification Type Description UL Certification Indicates suitability for hazardous locations with flammable gases, vapors, and dust. ATEX Certification Certifies equipment for use in potentially explosive atmospheres in the EU. IECEx Certification Assesses product conformity for hazardous areas, recognized globally. CSA Certification Ensures compliance with Canadian safety standards. NEC and CEC Compliance Outlines regulations for intrinsically safe equipment in North America.

With these safety features and ergonomic designs, ABS plastic telephone handsets truly stand out as reliable communication tools in industrial settings.

ABS plastic telephone handsets stand out for their durability, environmental resistance, and safety features. They resist moisture and corrosion, ensuring long-lasting performance in tough conditions. Additionally, their cost-effectiveness makes them a smart choice for industries. When selecting communication devices, consider these advantages to enhance your industrial setting.

FAQ

What industries benefit from ABS plastic telephone handsets?

Many industries, including manufacturing, construction, and logistics, benefit from ABS plastic telephone handsets due to their durability and resistance to harsh conditions.

How do ABS plastic handsets compare to other materials?

ABS plastic handsets offer excellent impact resistance and moisture protection, making them more suitable for industrial use than materials like PLA or PA6.

Are ABS plastic telephone handsets safe to use?

Yes, ABS plastic handsets are non-toxic and often meet safety certifications, ensuring they are safe for use in industrial environments.