Facilities with explosive gases, vapors, or dust must prioritize safety. Explosion-proof telephones protect employees by enabling critical communication in hazardous locations. Regulatory bodies enforce their use to prevent accidents. An industrial telephone handset designed for these environments ensures reliable operation and compliance with safety standards.

Key Takeaways

- Explosion-proof telephones provide safe, reliable communication in hazardous areas by preventing sparks or heat that could ignite flammable gases, vapors, or dust.

- These telephones are essential in industries like oil and gas, chemical plants, mining, grain storage, and wastewater treatment to protect workers and meet strict safety regulations.

- Facility managers should identify hazardous zones, follow regulatory standards, consult safety experts, and choose certified explosion-proof telephones with features that support emergency communication and durability.

What Is an Explosion-Proof Telephone?

Definition and Purpose

An explosion-proof telephone serves as a specialized communication device for hazardous environments. Facilities such as oil refineries, chemical plants, and mines rely on these telephones to maintain safe operations. Unlike standard telephones, explosion-proof models feature rugged construction and advanced safety certifications. Their design prevents ignition of flammable gases, vapors, or dust during use.

Explosion-proof telephones protect workers by enabling reliable communication in areas where a single spark could trigger a disaster.

The following table highlights key differences between explosion-proof and standard telephones:

| Feature | Specification | Benefit |

|---|---|---|

| Material | Durable composite polymer/metal | Withstands extreme temperatures, impacts, and corrosive environments. |

| Explosion Protection | Certified flameproof design (Ex d IIB T4) | Prevents ignition risks in hazardous zones. |

| Environmental Rating | IP68 (water and dust resistant) | Operates in harsh weather and submerged conditions. |

| Network Support | Wi-Fi, IP, Power over Ethernet (PoE) | Integrates with industrial networks, reducing wiring complexity. |

| User Interface | Backlit LCD, oversized tactile buttons | Allows use with gloves and in low-light environments. |

How Explosion-Proof Telephones Work

Explosion-proof telephones use scientific principles to prevent ignition in hazardous atmospheres. Manufacturers select materials that keep device surfaces below ignition temperatures. Strong, sealed enclosures contain any internal explosion, blocking flames or sparks from escaping. Intrinsic safety barriers limit electrical energy to non-ignitable levels.

The table below outlines these principles:

| Scientific Principle | Explanation |

|---|---|

| Temperature Control | Materials and design keep surfaces below ignition points. |

| Intrinsic Safety Barriers | Electrical energy remains too low to ignite explosive atmospheres. |

| Flameproof Enclosures | High-strength casings contain internal explosions and prevent spread. |

| Segregation | Sealed casings separate ignition sources from hazardous atmospheres. |

Explosion-proof telephones combine robust engineering and strict certification to ensure safe communication in the most demanding industrial settings.

Where Are Explosion-Proof Telephones Required?

Oil and Gas Facilities

Oil and gas facilities present some of the most hazardous environments in industry. Workers encounter flammable gases and vapors during extraction, refining, and transportation. Explosion-proof telephones serve as a critical safety measure, enabling reliable communication in areas where a single spark could trigger a catastrophic event. North America leads the market for explosion-proof communication devices due to strict safety regulations in the oil and gas sector. These facilities require intrinsically safe devices to prevent ignition of flammable materials and ensure compliance with regulatory standards.

Oil and gas sites rely on explosion-proof telephones to maintain operational safety and meet regulatory demands.

Common hazardous locations in oil and gas:

- Drilling rigs

- Refineries

- Storage tanks

- Pipeline compressor stations

Chemical Plants

Chemical plants handle volatile substances that can create explosive atmospheres. Safety protocols prohibit standard cell phones in explosive zones, including Zone 0, Zone 1, and Zone 2. Only intrinsically safe or explosion-proof communication devices are permitted. Industry standards such as API RP 500/505 and NFPA 497 guide these restrictions. Certified professionals must install explosion-proof telephones, and regular maintenance ensures ongoing compliance. These devices integrate with emergency response systems, providing immediate alerts during incidents.

Key safety practices in chemical plants:

- Clear demarcation of hazardous zones

- Personnel training on device use

- Integration with alarm systems

Chemical plants depend on explosion-proof telephones to prevent ignition risks and support emergency communication.

Mining Operations

Mining operations expose workers to flammable gases, dust, and harsh conditions underground. Explosion-proof telephones are essential for safe communication in coal and metal mines. Regulatory requirements include certifications such as ATEX (EU), IECEx (International), and Class I Division 1 or 2 (North America). These certifications mandate intrinsic safety design, sealed enclosures, and spark-proof components.

| Certification | Region/Scope | Purpose/Description |

|---|---|---|

| ATEX | European Union | Ensures safety in explosive atmospheres with intrinsic safety and sealed enclosures |

| IECEx | International | Confirms compliance with global hazardous area safety standards |

| Class I Div 1 or 2 | North America | Certification for equipment safe in hazardous locations with flammable gases or dust |

Explosion-proof telephones in mining environments feature rugged construction and high protection ratings, such as IP66 and IP68, to withstand dust, water, and extreme temperatures.

Grain Handling and Storage

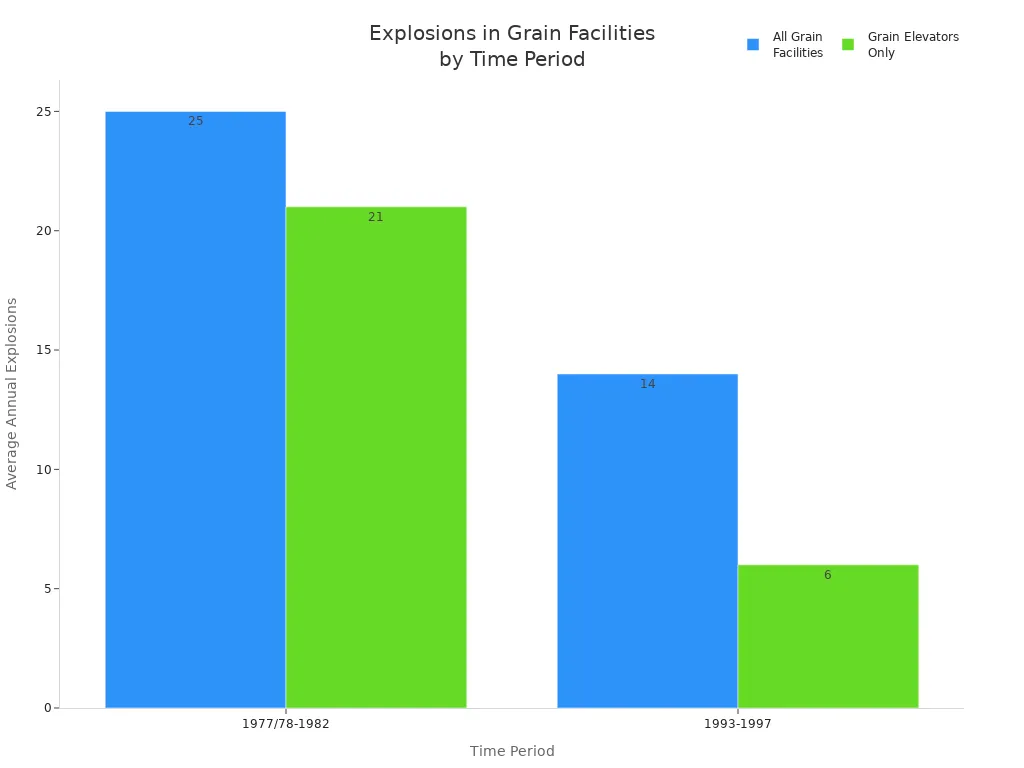

Grain handling and storage facilities face risks from combustible dust, which can ignite and cause explosions. The frequency of explosive incidents has declined significantly since the implementation of OSHA’s Grain Handling Facilities Standard. Improved safety awareness and regulatory controls have reduced average annual explosions and related injuries.

Explosion-proof telephones contribute to safety by enabling communication in hazardous zones, supporting emergency response, and helping facilities comply with regulatory standards.

Wastewater Treatment Plants

Wastewater treatment plants process flammable gases such as hydrogen sulfide and methane. NFPA 820 and NEC Article 501 govern the installation of explosion-proof telephones in these environments. NFPA 820 prescribes fire protection methods, ventilation, and physical separation to control flammable gases. NEC Article 501 defines Class I hazardous locations and requires explosion-proof enclosures to contain internal explosions and prevent ignition of the surrounding atmosphere. Proper installation and sealing of conduits minimize explosion risks.

Wastewater treatment plants rely on explosion-proof telephones to maintain safe operations and comply with fire protection standards.

Pharmaceutical Manufacturing

Pharmaceutical manufacturing environments demand strict safety and regulatory compliance. Explosion-proof telephones enhance safety by preventing accidents and containing potential explosions within the device. These devices ensure compliance with OSHA, NFPA, ATEX, and IECEx standards. Reliable communication supports uninterrupted production, increases productivity, and reduces costly downtime. Explosion-proof telephones also support digital transformation through VoIP compatibility, remote diagnostics, and integration with control systems.

Benefits of explosion-proof telephones in pharmaceutical manufacturing:

- Accident prevention

- Regulatory compliance

- Operational efficiency

- Cost savings

- Support for digital transformation

Paint Shops and Coating Facilities

Paint shops and coating facilities use volatile chemicals that create explosive atmospheres. Workers handle flammable solvents, paints, and coatings, which can produce hazardous vapors. Explosion-proof telephones provide safe communication in spray booths, mixing rooms, and storage areas. These devices help facilities comply with safety regulations and reduce the risk of ignition during routine operations.

Food Processing Plants

Food processing plants often contain combustible dust and gases. Gas lines and heaters used for cooking, drying, and sterilizing equipment can leak and cause explosions. Combustible materials such as grain dust, oils, and food particles create explosive atmospheres. Electrical systems with faulty wiring or equipment can generate sparks capable of igniting gases or dust.

Main hazards in food processing plants:

- Gas leaks from cooking and drying equipment

- Combustible dust from grains and food particles

- Electrical sparks from faulty wiring

Explosion-proof enclosures protect telephones and other devices by containing internal explosions and preventing ignition of the surrounding atmosphere. Hazardous zones in food processing plants require explosion-proof devices to ensure safety and regulatory compliance.

Power Generation Facilities

Power generation facilities, including those using fossil fuels, biomass, or renewable energy, operate in environments with flammable gases, vapors, or dust. Explosion-proof telephones are necessary in turbine halls, fuel storage areas, and control rooms where hazardous atmospheres may develop. These devices enable safe communication, support emergency response, and help facilities meet industry safety standards.

Explosion-proof telephones play a vital role in protecting workers and maintaining compliance across a wide range of hazardous industrial environments.

Safety Standards and Regulations

OSHA Requirements

OSHA enforces strict guidelines for hazardous locations. Facilities must use explosion-proof telephones in areas where flammable gases, vapors, or dusts exist. OSHA references standards from the National Electrical Code (NEC) and other regulatory bodies. Employers must ensure that all communication devices meet the required safety certifications. Regular inspections and maintenance help maintain compliance and protect workers from ignition risks.

NEC and IEC Hazardous Area Classifications

The NEC and IEC standards define hazardous locations using different systems. NEC uses classes, divisions, and groups to describe the type and likelihood of hazards. Class I covers flammable gases, Class II covers combustible dusts, and Class III covers fibers. Divisions indicate how often the hazard is present. IEC uses zones to classify risk levels internationally. Selecting the correct explosion-proof telephone depends on matching the device to the specific classification.

| Hazardous Location Type | NEC Classification | IEC Classification |

|---|---|---|

| Gas, vapor, mist | Class I, Division 1 | Zone 0, Zone 1 |

| Gas, vapor, mist | Class I, Division 2 | Zone 2 |

| Combustible dust | Class II, Division 1 | Zone 20 |

| Combustible dust | Class II, Division 2 | Zone 22 |

| Fibers and flyings | Class III, Division 1 | No Equivalent |

Understanding these classifications ensures that explosion-proof telephones prevent ignition in the specific hazardous atmosphere.

ATEX and IECEx Certification

ATEX certification is mandatory in Europe. IECEx provides a voluntary international standard. Both certifications require explosion-proof telephones to use corrosion-resistant materials and meet environmental protection standards such as IP66. Devices must display explosion protection markings and withstand harsh conditions, including extreme temperatures and corrosive atmospheres. Manufacturers must follow strict guidelines for construction, testing, installation, and maintenance.

- Certified for hazardous zones Zone 1 and Zone 2

- Markings like II 2G Ex e ib mb IIC T4 Gb

- Stainless steel or aluminum alloy housing

- IP66 protection rating

- Operating temperature from -25°C to +70°C

Local and Industry-Specific Regulations

Regulations vary by region and industry. North America relies on NEC, UL, and CSA standards, which emphasize robust enclosures. Europe prefers flame-proof equipment under ATEX and IECEx. Asia-Pacific combines local and international standards. The Middle East and Africa increasingly require ATEX and IECEx solutions, especially in oil and gas. Maintenance and installation requirements differ, with some industries needing regular inspections and precise sealing to maintain safety.

| Zone | Definition | Common Industries |

|---|---|---|

| Zone 0 | Explosive gas present continuously | Oil refineries, chemical plants |

| Zone 1 | Explosive gas likely during normal operations | Paint booths, fuel storage |

| Zone 2 | Explosive gas unlikely but possible | Fuel transfer, spray booths |

| Zone 20 | Combustible dust present continuously | Flour mills, coal plants |

| Zone 21 | Combustible dust occurs occasionally | Textile mills, food processing |

| Zone 22 | Combustible dust unlikely but possible | Warehouses, sawmills |

Explosion-proof telephones must comply with the relevant certifications and standards for each zone and industry to ensure worker safety and regulatory compliance.

How to Determine If You Need an Explosion-Proof Telephone

Identifying Hazardous Areas in Your Facility

Facility managers must take a systematic approach to identify hazardous areas. They assemble multidisciplinary teams that include plant engineers, safety staff, and operations personnel. The team classifies all locations where explosive atmospheres may exist. They review plant operations, materials, and processes, then consult with vendors to select suitable explosion-proof equipment. Managers ensure compliance with current standards and verify that installation matches design specifications. Alternative protection methods, such as pressurization or explosion-proof enclosures, may be considered when intrinsic safety is not feasible.

Key steps include:

- Classify hazardous areas using recognized systems.

- Collaborate with experts to determine area classifications.

- Select and install equipment designed for hazardous zones.

- Maintain ongoing compliance with evolving standards.

Assessing Risk of Explosive Atmospheres

Risk assessment forms the foundation for equipment selection. Teams evaluate the properties of dangerous substances, such as boiling point and flash point. They consider the size and extent of potential explosive atmospheres, including the quantity of hazardous materials and process conditions. Ventilation effectiveness and the presence of multiple substances influence the assessment. Maintenance activities and operational procedures receive careful review to identify possible ignition sources. Equipment selection depends on the frequency and duration of explosive atmospheres, guided by zone classifications.

Risk assessment best practices:

- Identify hazardous zones and substances.

- Evaluate process conditions and ventilation.

- Review operational procedures for ignition risks.

- Select equipment based on zone classification.

Reviewing Regulatory Obligations

Regulatory frameworks classify hazardous locations into zones based on the likelihood of explosive gases or vapors. These classifications dictate the required safety standards and certifications for electronic devices. Organizations must comply with standards such as ATEX, IECEx, NEC, UL, and CSA. Compliance ensures that explosion-proof telephones meet strict safety requirements and legal obligations. Regular maintenance and documentation support ongoing compliance and worker safety.

Regulatory obligations drive the selection and installation of certified explosion-proof telephones in hazardous environments.

Consulting with Safety Experts

Safety experts provide valuable guidance throughout the evaluation process. They help interpret standards, assess risks, and recommend suitable equipment. Collaboration with experts ensures that facility managers select devices that match the specific hazardous area classification. Ongoing consultation supports compliance, optimal protection, and continuous improvement in safety practices.

Practical Checklist for Decision-Makers

Key Questions to Ask

Decision-makers should start by asking targeted questions to clarify their facility’s needs.

- Does the facility contain areas classified as hazardous by NEC, IEC, or ATEX standards?

- What types of explosive atmospheres exist—gases, vapors, or dust?

- Which zones or divisions require explosion-proof telephones?

- Are current communication devices certified for hazardous locations?

- How often do inspections and maintenance occur for installed equipment?

- Who is responsible for compliance and recordkeeping?

Asking these questions helps leaders identify gaps in safety and compliance.

Steps for Evaluation

A structured evaluation process ensures thorough risk management.

- Map all hazardous zones within the facility.

- Review regulatory requirements for each area.

- Assess existing communication systems for certification and suitability.

- Consult with safety experts to confirm hazardous area classifications.

- Select explosion-proof telephones that match the zone or division.

- Schedule installation by certified professionals.

- Plan regular inspections and maintenance.

This approach supports both operational safety and regulatory compliance.

Documentation and Recordkeeping

Accurate documentation demonstrates due diligence and supports audits.

- Maintain detailed records of equipment, including specifications, model and serial numbers, and manufacturer information.

- Keep copies of ATEX or other certification documents for each device.

- Retain safety data sheets for hazardous substances.

- Document inspection dates, findings, corrective actions, and inspector names.

- Log all repairs and maintenance, noting dates, work performed, and technician details.

- Track certification renewals and recertification activities.

- Record any equipment modifications and related testing.

- Use electronic document management systems for easy retrieval and sharing.

- Implement digital reminders for upcoming inspections or renewals.

Comprehensive records help organizations prove compliance and respond quickly during audits or emergencies.

Choosing the Right Industrial Telephone Handset

Matching Handset Certification to Hazardous Area Classification

Selecting the correct industrial telephone handset starts with matching its certification to the hazardous area classification. Each environment presents unique risks, so the device must meet strict standards. The table below outlines key factors to consider:

| Factor | Explanation |

|---|---|

| Intrinsic Safety Design | Device must be battery-operated, self-contained, and designed to prevent ignition risks. |

| Relevant Certifications | Must meet certifications such as UL, ATEX, or IECEx for hazardous area compliance. |

| Applicable Standards | Compliance with IEC 60079-25 (design), 60079-14 (installation), and 60079-17 (maintenance). |

| Hazardous Area Classification | Device must be certified for the specific class (e.g., Class 1 Division 1, Zone 1/21, 2/22). |

| Energy and Heat Limitation | Design limits stored energy and heat generation under fault conditions. |

| System Integration | Device must integrate into a properly designed intrinsically safe system if not self-contained. |

A facility manager should always verify that the industrial telephone handset aligns with the exact hazardous zone requirements.

Features for Emergency Communication

An industrial telephone handset must deliver reliable emergency communication in hazardous environments. Devices require certifications like ATEX and IECEx to prevent ignition. Rugged, corrosion-resistant construction and weatherproof enclosures rated at IP66 or higher are essential. Key features include:

- Loud ringer (up to 90 dB at 1 meter) and flashing beacon for alerts

- Noise-canceling microphone for clear audio in noisy areas

- Programmable, glove-friendly keypad with emergency buttons

- Hermetically sealed hook switch for reliability

- Compatibility with analog and SIP/VoIP systems, supporting Power over Ethernet

- Mounting options for wall, column, or structure

These features ensure the industrial telephone handset supports safe, effective communication during emergencies in oil refineries, chemical plants, and mining sites.

Durability and Maintenance Considerations

Durability plays a critical role in selecting an industrial telephone handset. Devices must withstand harsh conditions, including explosive gases, dust, and extreme temperatures. Proper battery installation and maintenance keep safety features intact. Only qualified professionals should perform repairs or disassembly to maintain explosion-proof certification. Choosing handsets from reputable manufacturers ensures long-term reliability and compliance with safety standards. Regular inspections and correct handling help preserve the integrity of the industrial telephone handset, reducing the risk of failure in hazardous environments.

Explosion-proof telephones deliver reliable communication in hazardous environments. Their robust design and compliance with ATEX, IECEx, CSA, and UL standards support emergency response and routine operations.

Facilities should assess risks, consult safety professionals, and select certified devices to protect teams and maintain regulatory compliance.

FAQ

What makes a telephone explosion-proof?

Manufacturers design explosion-proof telephones with sealed enclosures and certified components. These features prevent sparks or heat from igniting flammable gases, vapors, or dust in hazardous areas.

Can explosion-proof telephones work outdoors?

Yes. Most explosion-proof telephones have weatherproof ratings like IP66 or IP68. These ratings ensure reliable operation in rain, dust, and extreme temperatures.

How often should facilities inspect explosion-proof telephones?

Facilities should schedule inspections at least once per year. Regular checks help maintain certification, ensure device integrity, and support compliance with safety regulations.