Industrial metal keypad construction sets a high standard for access control devices in demanding environments. Metal keypads withstand heavy usage, often lasting up to 15 years under extreme conditions, while plastic keypads degrade much faster. Industry standards, including IP65 and IK10 ratings, ensure reliable performance and robust security in harsh settings.

Key Takeaways

- Choose industrial metal keypads made from stainless steel or similar durable materials to ensure long-lasting performance in harsh environments.

- Look for keypads with high IP and IK ratings to guarantee protection against dust, water, and physical damage, ensuring reliable operation.

- Select keypads that combine strong security features like multi-factor authentication and tamper resistance with ergonomic and accessible designs for all users.

Reliability and Durability in Industrial Metal Keypad Design

Material Quality and Construction

Material selection forms the backbone of any industrial metal keypad. Manufacturers often choose stainless steel for its unmatched corrosion resistance and ability to withstand exposure to water, chemicals, and extreme temperatures. Stainless steel, especially grades 304 and 316, contains chromium, which creates a protective oxide layer. This layer prevents rust and staining, making these keypads ideal for harsh industrial settings. Aluminum alloy and titanium offer lightweight alternatives, but they do not match the ruggedness and longevity of stainless steel. Silicone rubber also plays a vital role in keypad construction. It provides cushioning, extends switch life, and acts as an EMI barrier, which is essential in environments with high electromagnetic interference.

Tip: Silicone rubber keypads offer enhanced tactile feedback, especially when operators wear gloves, and can be molded into larger, more accessible keys.

| Material | Durability Attributes |

|---|---|

| Stainless steel | High corrosion resistance, ruggedness, long service life, used for housings and key caps |

| Aluminum alloy | Lightweight, corrosion resistant but less durable than stainless steel |

| Titanium | Strong, corrosion resistant, lightweight but more costly |

| Silicone rubber | Provides cushioning, extends switch life, EMI barrier |

| Polycarbonate | Durable plastic, impact resistant |

| Composite materials | Carbon and resin composites offer abrasion and impact resistance |

Environmental Resistance and Weatherproofing

An industrial metal keypad must operate reliably in environments filled with dust, water, chemicals, and temperature extremes. High IP ratings, such as IP65, IP66, and IP67, indicate strong protection against solid particles and water ingress. For example, an IP67-rated stainless steel keypad resists corrosion, rust, and salt spray, and continues to function in temperatures as low as -40°C. These ratings ensure that keypads withstand water jets, immersion, and dust, making them suitable for washdown areas and outdoor installations.

Industrial keypads also face challenges from temperature fluctuations. Materials expand or contract with temperature changes, which can affect functionality. In extreme cold, batteries lose efficiency and touchpad sensitivity drops. In high heat, electronic components risk overheating, and materials may expand, causing misalignments. Manufacturers design industrial metal keypads to operate reliably from -40°C to 70°C, ensuring consistent performance in diverse climates.

Longevity and Maintenance Requirements

Long-term performance is a defining trait of a high-quality industrial metal keypad. Stainless steel construction ensures a long service life, often exceeding a decade even in demanding environments. However, several factors can threaten longevity:

- Poor sealant application may allow moisture and chemicals to enter, leading to corrosion and electrical failures.

- Design flaws, such as improper tail exit or excessive stack-up height, can cause mechanical stress and eventual failure.

- Inappropriate material choices may result in cracked overlays, dome collapse, or adhesive breakdown under temperature extremes.

- PCB-related issues, including soldering defects and component failures, can also reduce lifespan.

Routine maintenance remains minimal for well-designed keypads. Operators should inspect seals and housings periodically to prevent ingress of contaminants. Choosing an industrial metal keypad with robust construction and proper environmental sealing reduces the risk of failure and extends operational life.

Security and Usability Features of High-Performance Keypads

Advanced Authentication and Data Protection

Industrial access keypads have evolved far beyond simple PIN entry. Manufacturers now integrate advanced authentication methods to strengthen security and streamline user experience. Biometric authentication, including fingerprint, facial, and iris recognition, provides a unique layer of protection. These technologies rely on physical traits that are difficult to replicate, reducing the risk of unauthorized access. RFID card readers and smart cards offer fast, contactless entry, while mobile credentials using NFC or Bluetooth Low Energy enable secure access via smartphones and wearable devices.

Multi-factor authentication (MFA) combines two or more verification methods, such as a PIN plus a fingerprint scan or an RFID card plus facial recognition. This approach significantly lowers the chances of unauthorized entry. Industrial keypads often support external USB-connected biometric devices, as seen in Maple Systems’ cMT series HMIs, which allow configuration through dedicated software. The growing adoption of biometrics in industrial environments reflects their critical role in modern security protocols.

Note: Multi-factor authentication not only enhances security but also simplifies compliance with industry regulations by providing robust audit trails.

Tamper Resistance and Code Capacity

Tamper resistance stands as a cornerstone of industrial keypad design. Manufacturers employ rugged materials such as stainless steel to withstand physical attacks and vandalism. Circuit assembly encapsulation and epoxy-sealed electronics protect internal components from manipulation. Devices with IK10 impact resistance and IP65 ingress protection ratings resist both environmental hazards and deliberate tampering.

| Design Feature | Description/Benefit |

|---|---|

| Stainless Steel Construction | Provides ruggedness and physical durability |

| Circuit Assembly Encapsulation | Protects internal electronics from tampering |

| IK10 Impact Resistance Rating | Ensures high resistance to physical impact and vandalism |

| IP65 Ingress Protection Rating | Prevents dust and water ingress, enhancing durability |

| Epoxy Encapsulated Electronics | Further protects circuitry from environmental damage |

| Low Profile Design | Reduces exposure to tampering attempts |

| Built-In Switch Monitoring | Detects unauthorized attempts to manipulate switches |

| Audible and Visual Indicators | Enhances user authentication and reduces unauthorized access |

Industrial keypads detect tampering attempts using several innovative techniques. A fine wire mesh beneath the keypad overlay forms a continuous electrical path. If drilling or intrusion occurs, the mesh breaks and triggers an alert. Electrical continuity checks between the rubber keypad and PCB signal tampering if the overlay is removed. Capacitive sensors monitor changes in capacitance, detecting foreign objects or bugs. Microcontrollers scan both keypad inputs and mesh integrity, halting operations if anomalies arise. Manufacturers also bury vias inside PCB layers and use pseudo-random scanning sequences to further increase tamper resistance.

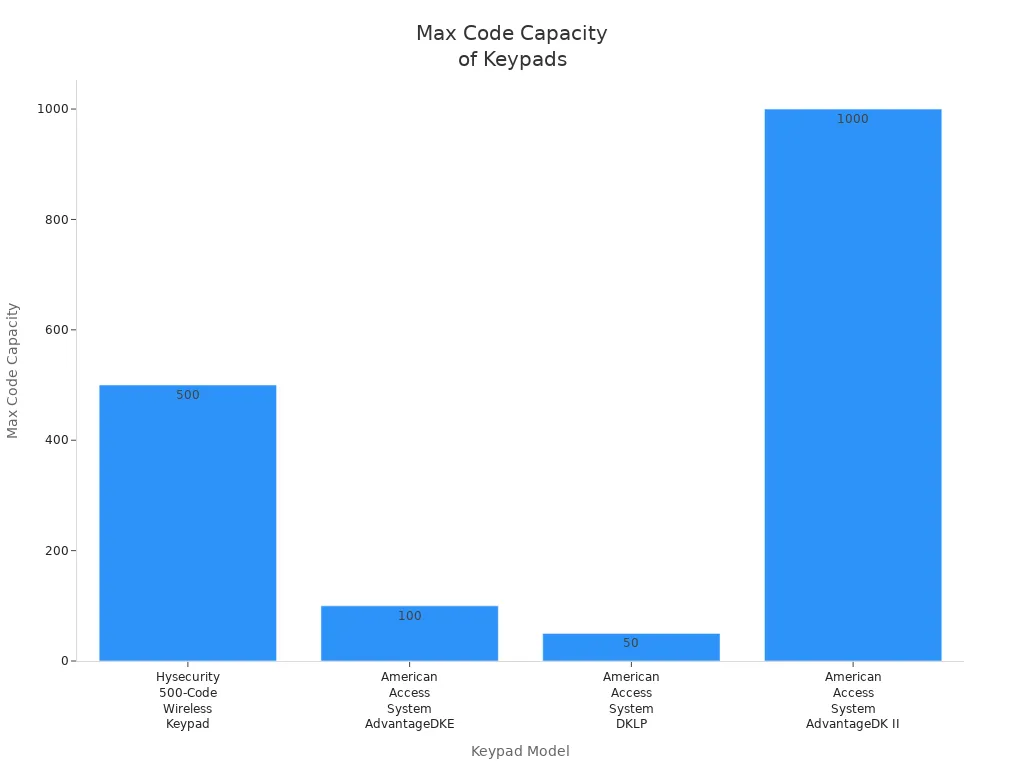

Code capacity determines how many unique access codes a keypad can store. Leading models support hundreds or even thousands of codes, allowing flexible access management for large facilities.

| Keypad Model | Maximum Code Capacity | Notes |

|---|---|---|

| Hysecurity 500-Code Wireless Keypad | 500 | Wireless keypad, suitable for high security applications |

| American Access System AdvantageDKE | 100 | Standalone keypad, metal enclosure |

| American Access System DKLP | 50 | Low power, solar application keypad |

| American Access System AdvantageDK II | 1000 | Master controller, supports 5-digit codes, highest capacity among listed keypads |

Tip: High code capacity enables administrators to assign unique codes to individual users, track access events, and quickly revoke credentials when necessary.

User Interface and Accessibility

Usability remains a critical factor in industrial keypad design. Ergonomic features such as appropriate key spacing and optimized layouts reduce repetitive strain injuries and improve productivity. Customization allows manufacturers to include only necessary keys, minimizing errors and simplifying operation. Safety features like emergency stop keys enhance operational safety, while non-reflective surfaces improve visibility in low-light conditions.

- Larger keys and high-contrast labels support users with visual impairments.

- Adjustable tilt angles accommodate different user postures.

- Split and contoured keyboards promote neutral wrist and arm positioning, reducing fatigue.

- Designs minimize unnecessary movements and cognitive load, boosting productivity.

Industrial keypads also prioritize accessibility for users with disabilities. Manufacturers involve users in testing and feedback, ensuring products meet diverse needs. Customizable layouts and adjustable key switches allow users to tailor the device to their abilities. Integration with assistive technologies, such as eye-tracking, voice recognition, and switch access, expands usability. Keyboard accessibility ensures all mouse functions can be performed via keyboard, supporting users with visual or mobility disabilities.

Callout: User-centered design and compliance with accessibility standards, such as WCAG 2.1 Level AA, ensure that industrial keypads remain operable for all users.

ADA compliance requires keypads to be installed at a height between 34 and 48 inches above the floor, with clear floor space for wheelchair access. Buttons must have adequate size and spacing, and visual contrast aids users with limited dexterity or visual impairments. Braille and tactile signage help visually impaired users operate the keypad independently. Programming options, such as customizable codes and voice recognition, further enhance accessibility.

- Install keypads between 34 and 48 inches above the floor.

- Provide clear floor space and maneuvering clearance.

- Ensure buttons have adequate size and spacing.

- Use visual contrast between buttons and background.

- Incorporate Braille and tactile signage.

- Offer customization and voice recognition options.

- Maintain regular inspection and cleaning for ongoing compliance.

Industrial access keypads that combine advanced security features with ergonomic and accessible design deliver superior performance in demanding environments. These devices protect assets, support diverse user needs, and ensure reliable operation for years to come.

A high-performance industrial metal keypad delivers durability, environmental resilience, advanced security, and user-friendly design.

Decision-makers should select keypads that comply with industry standards for optimal reliability.

| Key Feature | Benefit |

|---|---|

| Metal Construction | Superior wear and corrosion resistance |

| Environmental Proof | Reliable in harsh conditions |

| Security | Advanced authentication and tamper resistance |

| Usability | Ergonomic and accessible design |

FAQ

What does an IP65 rating mean for an industrial keypad?

An IP65 rating means the keypad resists dust and low-pressure water jets. This protection ensures reliable operation in harsh industrial environments.

How often should operators maintain industrial metal keypads?

Operators should inspect seals and housings every six months.

- Clean surfaces regularly

- Check for signs of wear or damage

Can users customize key layouts for specific applications?

Yes. Many manufacturers offer customizable key layouts.

| Feature | Benefit |

|---|---|

| Custom keys | Improved workflow |

| Large buttons | Easier operation |