Selecting a rugged telephone handset for industrial environments requires attention to reliability, safety, and construction. Studies show frequent hardware and software failures, such as screen or audio issues and memory access violations.

| Failure Mode Category | Specific Failures Identified |

|---|---|

| Hardware Failures | Screen, audio, battery, charging, keyboard failures |

| Software Failures | Memory access violations, heap management problems |

A proven design with strong certifications and durable materials reduces costly downtime.

Key Takeaways

- Choose a rugged telephone handset with strong protection against dust, water, impacts, and chemicals to ensure reliable use in tough industrial conditions.

- Look for key certifications like MIL-STD-810, ATEX, and IECEx to guarantee safety and compliance in hazardous environments.

- Select handsets with practical features such as noise cancellation, long battery life, and secure mounting to improve communication and worker safety.

Understanding Harsh Industrial Conditions

What Defines Harsh Conditions?

Harsh industrial conditions challenge the durability and performance of telephone handsets. These environments often expose equipment to extreme weather, physical impacts, and operational hazards. Telecommunications literature frequently cites several factors that define such conditions:

- Natural disasters, including hurricanes, floods, earthquakes, and tsunamis, can cause widespread destruction.

- Physical damage to infrastructure, such as cell towers and cables, disrupts communication.

- Power outages and traffic paralysis further complicate operations.

- Severe weather, like snow, heavy rain, and fog, weakens wireless signals.

- Network congestion during emergencies increases communication difficulties.

- Building collapses and infrastructure failures lead to economic losses and hinder disaster response.

These challenges demand robust devices that maintain reliable communication when it matters most.

Common Industrial Environments and Challenges

Industrial environments present a range of hazards that require specialized handsets. The following table highlights typical temperature ranges and environmental challenges:

| Device Type | Operating Temperature (°C) | Storage Temperature (°C) |

|---|---|---|

| Consumer Devices | 0 to 35 | N/A |

| Rugged Devices | Up to 50 | Up to 60-70 |

Rugged devices also resist high humidity and dust, which are common in manufacturing, logistics, and construction. Industries such as oil and gas, public safety, and healthcare demand devices that withstand impacts, moisture, and extreme temperatures. Logistics and field services require handsets that function reliably outdoors and support features like barcode scanning or push-to-talk. These sectors rely on rugged handsets to ensure safety and operational continuity in demanding conditions.

Essential Features of a Rugged Telephone Handset

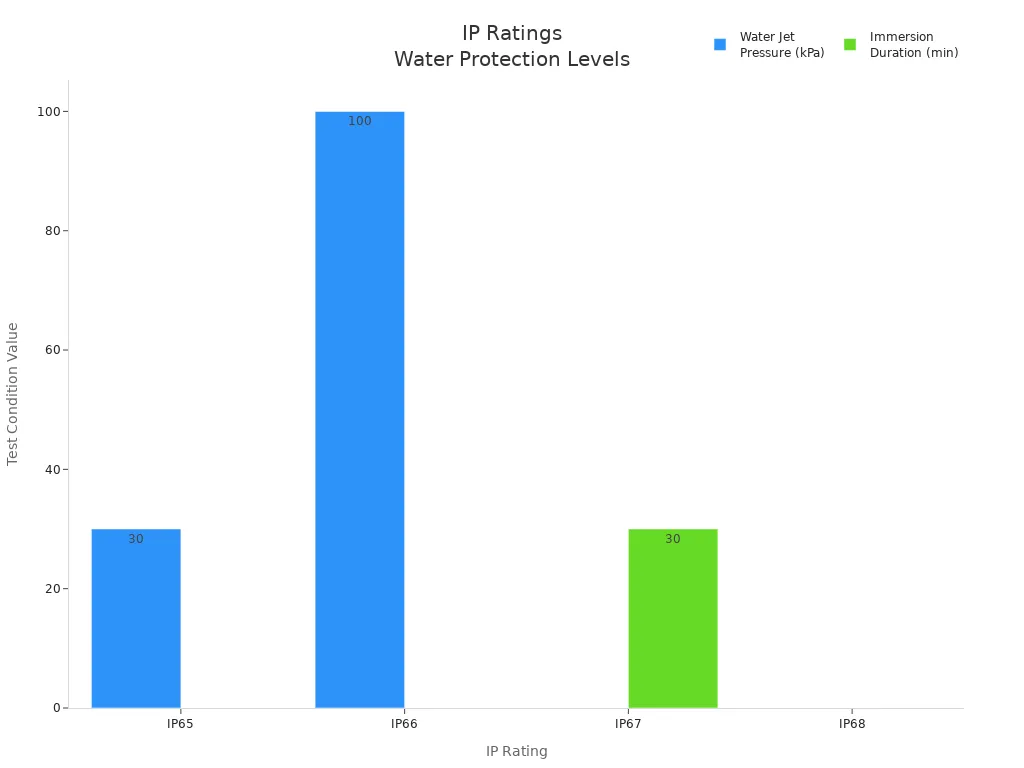

Ingress Protection (IP65, IP66, IP67, IP68)

A rugged telephone handset must withstand dust, water, and other environmental hazards. Ingress Protection (IP) ratings define the level of protection against solids and liquids. The first digit in the IP code represents dust protection, while the second digit indicates water resistance.

| Protection Aspect | IP Rating Level | Description |

|---|---|---|

| Dust Protection | 6 | Dust-tight: No ingress of dust; complete protection against contact. |

| Water Protection | 5 | Protection against low-pressure water jets from any direction. Suitable for water splashes and jets but not immersion. |

An IP65 rating ensures total dust protection and resistance to water jets, making it suitable for wet or dusty industrial environments. Higher ratings, such as IP66, IP67, and IP68, offer increased water resistance. IP66 withstands powerful water jets, IP67 protects against temporary immersion up to 1 meter for 30 minutes, and IP68 allows for continuous immersion beyond 1 meter, with conditions set by the manufacturer.

Selecting the correct IP rating ensures the rugged telephone handset remains operational in environments with dust, water sprays, or occasional submersion.

Impact Resistance (IK Ratings, Vandal Resistance)

Industrial settings expose devices to frequent impacts and potential vandalism. The IK rating, defined by IEC 62262, measures a device’s ability to withstand mechanical impacts. The scale ranges from IK00 (no protection) to IK10 (highest protection).

| IK Rating | Impact Energy (Joules) | Protection Description |

|---|---|---|

| IK06 | 1 | Suitable for industrial handsets; withstands 1 joule impact |

| IK08 | 5 | Strong impact resistance, common in industrial settings |

| IK10 | 20 | Highest standard impact resistance, ideal for heavy abuse |

A rugged telephone handset should have an IK rating of at least IK06, with IK08 or IK10 preferred for harsher environments. Vandal-resistant models often withstand tensile forces between 100 and 200 kilograms, ensuring durability even under deliberate abuse.

Temperature and Flame Resistance (UL94V0)

High temperatures and fire risks are common in industrial environments. UL94V0 certification ensures that handset materials self-extinguish flames within 10 seconds and do not produce flaming drips. This property minimizes fire spread and maintains the handset’s structural integrity during heat stress. Devices with UL94V0-rated components operate reliably in chemical plants, refineries, and mining sites, where fire safety is critical. These handsets also resist shocks, dust, humidity, and extreme temperatures, providing consistent performance in hazardous areas.

Chemical and Corrosion Resistance

Chemical exposure can degrade handset materials, especially plastics and circuit boards. Substances such as brominated flame retardants, phenols, and chlorinated compounds, along with metals like copper, accelerate material breakdown during thermal events. To combat this, manufacturers use corrosion-resistant materials and coatings.

| Material / Feature | Description / Benefit |

|---|---|

| 6mm thick aluminum alloy die-casting | Provides high strength and resistance to deformation |

| 304 stainless steel hinge | Enhances explosion resistance and corrosion resistance |

| WF2-grade anti-corrosion coating | Protects against strong acids and alkalis |

| All-metal aviation-grade casting | Achieves IP68 ingress protection, blocks dust effectively |

A rugged telephone handset with a die-cast aluminum case, stainless steel components, and anti-corrosion coatings resists damage from acids, alkalis, sea water, and harsh weather. These features extend the device’s lifespan in demanding environments.

Key Certifications (MIL-STD-810, UL, ATEX, IECEx)

Certifications validate a rugged telephone handset’s ability to perform safely and reliably. Each certification addresses different hazards and regulatory requirements.

| Certification | Primary Focus | Geographic Relevance | Key Features and Testing Requirements |

|---|---|---|---|

| MIL-STD-810H | Durability and environmental stress testing | Global | Tests for temperature extremes, mechanical shock, vibration, humidity, and simulated explosive atmospheres. |

| UL 913 | Intrinsic safety limiting electrical and thermal energy | North America | Prevents ignition in hazardous locations by controlling electrical and thermal output. |

| ATEX Directive 2014/34/EU | Explosion safety in hazardous zones | Europe | Prevents sparks and controls heat in explosive atmospheres, requires IP66 rating. |

| IECEx | Global explosion protection and certification | International | Ensures explosion safety through rigorous testing and ongoing surveillance. |

A handset with these certifications meets global standards for durability, explosion protection, and electrical safety, making it suitable for use in hazardous and regulated environments.

Additional Practical Features (Noise Cancellation, Battery Life, Mounting Options, Armored Cords)

Practical features enhance usability and safety. Noise cancellation technology, including Active Noise Cancellation (ANC) and Digital Signal Processing (DSP), filters out background noise and emphasizes speech. This ensures clear communication in environments with loud machinery or high ambient noise.

- ANC detects and cancels ambient noise in real time.

- DSP enhances voice clarity and suppresses unwanted sounds.

- Advanced headsets combine hearing protection with situational awareness, allowing users to hear warning signals while blocking harmful noise.

Other essential features include:

- Long battery life for uninterrupted operation during extended shifts.

- Multiple mounting options for wall, desk, or vehicle installation.

- Armored cords and reinforced connectors to prevent damage from pulling or twisting.

A rugged telephone handset equipped with these features supports mission-critical communication, improves worker safety, and reduces maintenance needs in industrial settings.

Matching Rugged Telephone Handset to Use Case

Chemical Plants and Hazardous Areas

Chemical plants and hazardous areas demand devices engineered for safety and compliance. Intrinsic safety certifications such as ATEX, IECEx, and UL Class I Division 1 ensure that the handset prevents electrical sparks or thermal energy from igniting flammable substances. These certifications are mandatory for legal operation and worker protection. Devices must also feature waterproof and dustproof ratings like IP68, long battery life, built-in security systems, reliable signal reception, and explosion-proof construction. Regular smartphones lack these safeguards and pose ignition risks.

Tip: Always verify certification markings such as Ex i and zone classifications before deploying any device in hazardous zones.

| Region / Use Case | Mandatory Certification(s) | Electrical Standard | Regulatory Body |

|---|---|---|---|

| European Union (EU) | ATEX | EN 60079 | European Commission |

| International / Global | IECEx | IEC 60079 | IECEx Management Committee |

| North America | NEC / UL / FM | NEC 500/505 | OSHA / NRTL |

| Canada | CSA | CEC | CSA Group |

Warehouses and Manufacturing Floors

Warehouses and manufacturing floors require handsets with robust mounting options and secure installation. Durable mounts withstand vibrations and rough handling. Integrated charging capabilities keep devices ready for use. Versatile mounting points allow flexible placement, improving accessibility and safety. Universal brackets compatible with electrical conduit boxes and NEMA-rated enclosures protect devices from moisture and vibration. Secure mounts with metal pins or padlocks prevent loosening in high-traffic areas.

- Pipe and electrical box mounting techniques improve accessibility.

- Position cables to exit from the bottom of enclosures to avoid moisture ingress.

Outdoor and Remote Sites

Outdoor and remote sites challenge connectivity and device durability. Scarcity of cell towers, geographical obstacles, and severe weather often weaken signals. Rugged telephone handsets designed for these environments use satellite networks to maintain global coverage. Devices built to military-grade standards resist shock, water, dust, and extreme temperatures. Integrated GPS tracking, SOS emergency buttons, and encrypted communication enhance safety. Long battery life supports extended use, while features like push-to-talk and thermal imaging improve operational efficiency.

- Satellite phones operate independently of cellular networks, ensuring communication in deserts, mountains, and offshore rigs.

- Rugged smartphones certified to MIL-STD-810H and IP68 provide reliable performance in construction, oil and gas, and emergency services.

Quick Reference Checklist for Selection

- Confirm required certifications for your region and use case.

- Check for IP and IK ratings suitable for environmental hazards.

- Evaluate mounting options for durability and accessibility.

- Assess connectivity solutions, including satellite capability for remote sites.

- Ensure long battery life and security features meet operational needs.

Selecting a rugged telephone handset with the right certifications and robust materials ensures long-term reliability and safety. Companies benefit from reduced downtime, fewer replacements, and improved compliance.

| Aspect | Long-term Cost Benefit |

|---|---|

| Warranty Period | Lowers repair and replacement expenses |

| Durability Standards | Minimizes device failure and downtime |

- Chemically strengthened glass and high IP ratings extend device lifespan.

- Durable construction reduces failures from drops and environmental exposure.

FAQ

What does an IP68 rating mean for an industrial handset?

An IP68 rating means the handset resists dust completely and survives continuous immersion in water. This rating ensures reliable operation in wet or dusty environments.

How do IK ratings affect handset durability?

IK ratings measure resistance to mechanical impact. Higher IK numbers, such as IK08 or IK10, indicate stronger protection against drops, strikes, or vandalism.

Why are certifications like ATEX and IECEx important?

Certifications like ATEX and IECEx prove the handset meets strict safety standards. These certifications allow safe use in explosive or hazardous industrial areas.